“… Does Nobody request no longer Orders or large quantities but shorter runs and customised products? …”

“… Is beginning to feel the increasing need for a tool that is capable of cutting and creasing any material quickly? … And at the same time without being heavily affected by the impact of fixed costs? …”

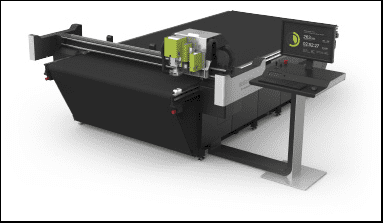

Kongsberg cutting tables are an excellent answer to these needs because they are fast and able to guarantee dieless cutting. They manage a wide variety of media and a large quantity of material.

Packaging, displays, signage, vinyl, corrugated cardboard, forex, dibond, plexiglass: Whatever products and materials are involved, the addition of finishing services to its portfolio allows a company to stand out from the competition.

In recent years, the world of digital cutting has evolved, both in terms of quality and speed. Historically linked to the world of prototyping and short production runs, today’s cutting plotters can fearlessly face more substantial production runs thanks to their powerful and fast engines, a more extensive range of tools and above all devices for the automated handling of the most dependable and “industrial” of materials.

Kongsberg is the first technology designed specifically for packaging and digital printing finishing. The full line of Kongsberg plotters offers a complete cutting solution for any type of job.

From the production of signs and outline shapes to production for exhibitors and displays, with different adjustments of speed and productivity based on the needs of customers and on the type of production desired.

A PLOTTER KONGSBERG FOR EVERY NEED

For Samples and small production

The solution for the production of samples using a wide range of different materials and with the right mix of quality and speed. Suitable for machining small runs of outline shapes and printed samples.

For high Volume Production of Packaging, Sign and Displays

The solution for precise high-speed production designed specifically to handle complex jobs using different materials in an active environment 24 hours a day, seven days a week.

[embedyt] http://www.youtube.com/watch?v=EjAY-g69gxA[/embedyt]

[embedyt] http://www.youtube.com/watch?v=xzS78quW6sI[/embedyt]

THE KONGSBERG MODELS

Kongsberg XE

Digital cutting plotter of limited size. Designed to provide a rapid and high quality solution for producing samples and the production of folding cartons in short runs. The XE plotter offers high levels of speed and accuracy combined with very simple operation.

Download Brochure

Kongsberg C

The perfect choice for the production of short runs developed from the existing Kongsberg C line. Now expanded to include smaller sized tables. It is designed to offer the best productivity and has a speed of 100 m/min and dimensions of up to 3,210 x 3,200 mm.mm

Scarica Brochure

[embedyt] http://www.youtube.com/watch?v=mVwDn_G4Ty8[/embedyt]

Kongsberg X

The perfect choice for doing versatile and creative work, with an excellent quality/performance ratio and a speed of 50 m/min. The X line is available in six different models with dimensions from 1,680 mm x 1,270 mm (66” x 50”) to 2,210 x 6,550 mm (87” x 258”).”).

Download Brochure

[embedyt] http://www.youtube.com/watch?v=mVwDn_G4Ty8[/embedyt]

Kongsberg XP AUTO

Ideal for the production of packaging and POP displays in small runs. XP Auto can cut directly from CAD projects, allowing production to be started right away without the expense of preparing a die. Kongsberg XP Auto improves profitability for converters who do short runs and on-demand jobs. In this way, you can accept small-volume, but highly profitable, orders from companies that prefer to order and purchase from a single supplier

Download Brochure

The Kongsberg Automation Systems

[embedyt] http://www.youtube.com/watch?v=ydG2bSfLb3A[/embedyt]

[embedyt] http://www.youtube.com/watch?v=qnpcxPjW864[/embedyt]

To further eliminate the downtime of the machine and operator, and to exploit the true potential of the Kongsberg tables, it is possible to use job scheduling across multiple areas. Such areas can be loaded with material independently. While the material is processed in one area of the table, the operator (or robot) loads and prepares the other area for the finishing. The operator’s downtime is drastically reduced. The cutting plotter works almost continuously.errottamente.

The IBF feeder can handle pallets of materials with multiple stacks at high speeds. It is can be accessed by forklift. It is an indispensable tool for all applications requiring medium-to-high run lengths. The feeder offers great flexibility. It can be used in conjunction with a roll feeder for flexible materials without having to exchange the board feeder.nnelli.

KNIVES BLADES AND DRILLS KONGSBERG

You can find blades, oscillating knives, drills, pens, cords and all the tools available for Kongsberg plotters at our SHOP by clicking on the image on the side of this page.

Go to shop

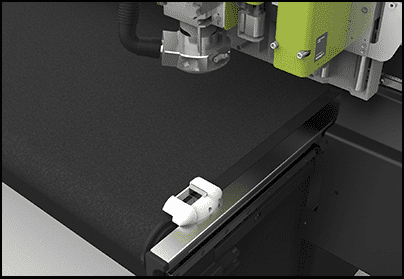

Auto Tool Adjust automates the configuration of a tool according to the media selected. One of the main innovations of the Auto Tool Adjust function is the integration of a complete database of materials. This is based on decades of experience in digital finishing. The operator receives advice from the system about the selection and configuration of tools and blades when they are configuring the job. Such information can help remove uncertainties from the production finishing processes. It accelerates job substitutions and the entire production, as well as improving uniformity. The risk of damage to expensive materials, and of obtaining variations in terms of quality, is drastically reduced.

I SOFTWARE KONGSBERG

The i-cut Production Console (iPC) handles all the functionality of the Kongsberg tables. Optical inspection with video camera, start up, tool recognition, calibration and tool adjustment. The iPC instinctively assists the machine operator, communicating using colours and drawing attention to the right item at the right time. It will change the way operators perform the finishing of jobs and allow them to get even more from their machines.

Download Brochure

Accurate production planning and the assigning of priority for the activity of digital finishing have been simplified thanks to the new Esko Device Manager solution. It ensures absolute control of production finishing. The job being run, the status and code of all the connected devices are clearly displayed on the screen. The software determines the optimal arrangement of the sheets in order to improve production capacity. The operators can use an intuitive drag and drop interface to assign priority to the table codes. They can insert urgent jobs and even balance the workload between the different tables. The Device Manager can also be connected to the more complete Esko workflow solution, the Automation Engine.

[embedyt] http://www.youtube.com/watch?v=AsyxWXTsIsI[/embedyt]

[embedyt] http://www.youtube.com/watch?v=JOCi6LjkbAo[/embedyt]